What Are PCB And Its Advantages?

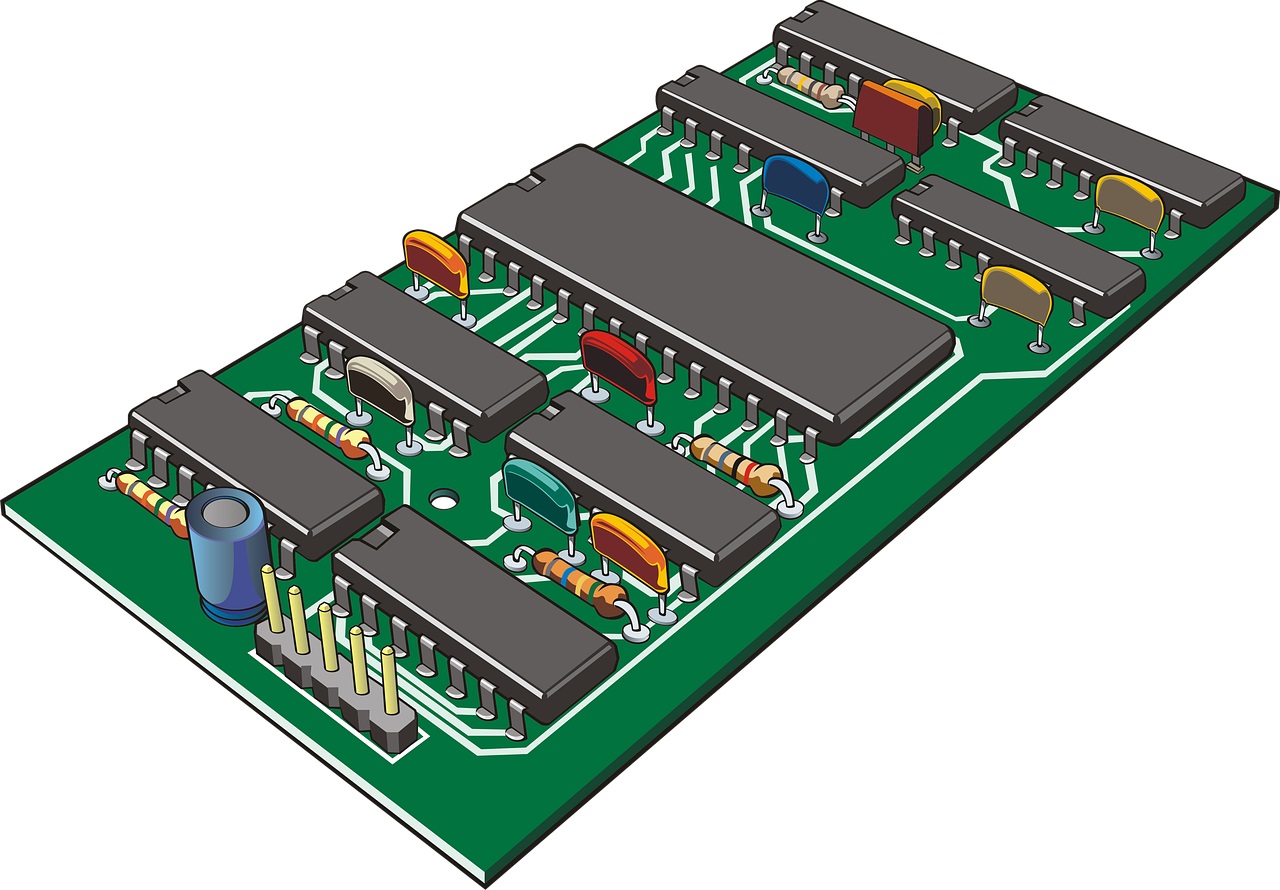

Printed circuit boards are crucial in modern electronics, where every electronic component can be compiled on a single board to give a complete circuit. The components connect with the trace on the board in a slide-to-slide manner, making it perform several electronics tasks.

In a printed circuit board, the number of circuits is very large, where manufacturers need to add some small-sized electronic components and make them operable.

PCB’s mechanical and electrical attributes can give several applications in the industries, and most of the printed circuit boards manufactured today are rigid printed circuit boards. Also, there is a large variety of PCBs in the market in which multilayer printed circuit boards are getting popularity in combining several circuits on the different layers of PCB board.

Panel mount assembly has speeded to electronics devices’ operation quality, and components like semiconductors, resistors, and diodes are mounted on the printed circuit board. The PCB makes them talk with each other with the circuit connection, making it easy to operate in several applications.

Businesses require printed circuit boards because they can provide ample of solutions related to electronics.

Table of Contents

What Industries Are Using Printed Circuit Boards?

With a very quick electronics approach, printed circuit boards are very lightweight and small, making them appropriate in electronics applications. All the modern devices are compatible with the printed circuit boards, and it helps them integrate complex systems on a single board.

The cost of production gets pennyworth for the businesses, and it is the major reason everyone is considering printed circuit boards in the industries.

Aerospace

Aerospace industries need printed circuit boards for instruments, panels, dashboards, flight controls, and safety systems, where they are using rigid, flexible, and rigid-flex PCB. Aerospace technology is growing with advanced technology, and the need for small circuits is necessary for the operations.

Complex printed circuit boards are used in aircraft, satellite drones, and all aerospace electronics. These components need durability, and rigid-flex PCBs can provide the highest vibration absorbing ability. This will enhance the durability of the printed circuit boards in every situation.

PCBs reduce the weight, equipment, fuel consumption, and several crucial factors in aerospace operations. Printed circuit boards can provide all the crucial things that can take the industry to a paramount.

Military

The military sector has a very large PCB use because military services are frequently exposed to shock, heavy impact, and vibration management. The military sector equipment is very bulky, requiring some small printed circuit boards to manage everything efficiently.

Military vehicles, computers, and modern weapons need durable printed circuit boards to meet all the crucial military operations. Printed circuit boards can provide smart targeting and surveillance to the military services, giving crucial information to the military sector.

Now the military services have a huge demand for small printed circuit boards that can withstand ample off weight of g-force without getting a failure.

Commercial Electronics

The printed circuit boards are becoming crucial in Industrial and commercial electronics that can manage everything from manufacturing to supply chain. The automation process has given efficient results to the industries where they can rely on electronic equipment to enhance productivity and reduce cost.

Flexible and rigid-flex PCBs can help manufacturers to produce lightweight printed circuit boards that can provide every function with efficient results. Systems like cameras, mobile, electronics, and computers need printed circuit boards to get fast operations.

Benefits Of PCBs In The Current Industrial Era

Printed circuit boards have several applications in the current electronics world, where manufacturers are getting instant solutions placing the electronic components. Long ago, the circuits were the complex web of wires, and electronic equipment was not safe. Still, printed circuit boards have created a revolution where every component is combined on a single board using the tracks.

Compact Size And Reduced Wiring

All the electronic components are attached to a board and connected with copper tracks instead of wires. The components are very small in size, which reduces the size of a printed circuit board and uses a simple platform to arrange ample electronic components in an efficient and compressed manner.

Repairing And Diagnosing Became Convenient

If the electronic device is getting any damage, then PCB has made it easy to check and repair the particular failure. There is no need to check every circuit to diagnose the printed circuit board failure. Also, the PCB devices are mentioned on the board, which helps understand the fault.

The repair process and installation process become convenient for the engineers, and they can save a lot of time in diagnosing and repairing the electronic devices.

Reduced Noisy Machines

PCB gives less electronic noise if it is properly laid out on the device, which will give perfect performance to the circuit. Also, the manufacturers design the PCB so that the path length of the electric current becomes shorter.

It can reduce the radiation and electromagnetic waves from the PCB, giving a better connection to the components, crucial in electronics.

Cost Reduction

Printed circuit board manufacturing has reduced the cost of production with all the advanced circuits on the board. Manufacturers can use an automation process to understand the PCB operation and create a better operating device with all the crucial equipment.

Conclusion

Printed circuit boards are the revolution in modern electronics, where everything depends on electronic devices’ operation. The military sector, Aeronautics sector, Aerospace, and IT sector need printed circuit boards that make it worthwhile in several applications.