Advantages of Magnetic Workholding

Workholding is a device to secure a workpiece while machining. It can be as diverse as a simple clamp or a complicated crankshaft pin milling chuck. Regardless of its nature, workholding is a critical element on a machining centre as it provides the precise position and orientation for a workpiece. There are several workholding options, including magnets.

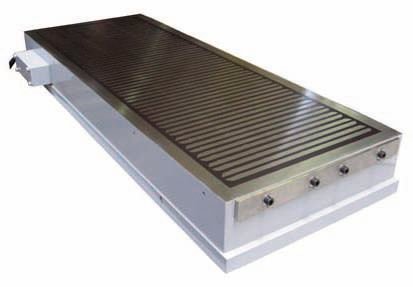

The type mostly depends on the part and the device should be able to secure the part without causing any damage to it. Magnets are excellent alternatives to mechanically holding workpieces for machining as well as for holding workholders such as visors and fixtures on the machine tool table. Magnets are found in general machine shops that look to reduce setup, increase access, or to simplify their workholding approach.

How to select the right workholding?

The right workholding device can save time, increase production and ensure better safety. It is always better to select the workholding based on factors such as material being cut, tolerance requirements, shape, weight, thickness, and batch size. Irregular workpieces and thin-wall components might need customised solutions. Furthermore, modern-day manufacturing requires superior accuracy and repeatability.

Why choose magnetic workholding?

Choosing the correct workholding is the key to maximising productivity because how a part of the machine is held is as crucial as how it is cut. A wide range of magnetic chucks is available for grinding, milling, and cutting applications.

Magnetic workholding has become a popular choice mainly because they offer the following advantages:

- Vast improvements in production efficiency.

- Magnetic workholding makes faster set up, feed rates, and metal removal possible. It can result in a 500% increase in units per hour output.

- They bring down the clamping time to a minimum. It is possible to go for an instant location without any manual clamping.

- Magnetic workholding systems offer continuous 5 face machining. It means that there is no need to stop and re-position every now and then.

- Magnetic chucks offer excellent access and allow through machining, cutting, and drilling.

- More importantly, they offer improved safety. Magnetic technology is failsafe and guarantees a secure hold thereby eliminating any chances of hazards.

- Magnetic workholdings offer superior precision and 100% consistent clamping. There are no operator variations.

- They also eliminate vibration or chatter. This, in turn, leads to a longer tool life with improved accuracy.

- Magnetic chucks are the ideal for multi-part and multi-directional machining.

- They are best suited for thin-walled or sensitive workpieces as they do not warp or twist, and are not crushed by forces applied at a point.

- Magnetic workpieces can be clamped with magnetic pole extensions. These movable pole extensions can adapt to workpiece contours and they have ample support to rest on the extensions.

Thus, magnetic workholdings come with several advantages and flexibility, making them a popular choice for those working in machining centres.